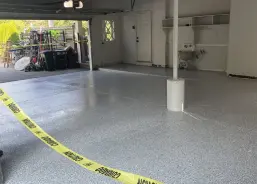

Why Comer & Cross Uses Polyaspartic Instead Of Epoxy?

Comer & Cross Concrete Coatings has completed 900+ coating projects. The projects consist of garages, basements & commercial spaces. Our installation crews have tried a number of products that claim to be long lasting solutions for both new and damaged concrete floors.

At first, we used epoxy. It was promised by suppliers as a solution that would look fantastic and hold up against the harsh winter months for years. Unfortunately, only one of those promises were true. Epoxy performed for the first 6-12 months and then tended to go on a downward spiral.

Epoxy has a tendency to peel, delaminate and has a lifespan of only 2-4 years.This product did not meet the standard for Comer & Cross and our clients.

Ever since our realization, Comer & Cross has been committed to polyurea/polyaspartic coating systems that meet our criteria for appearance and durability.

Our pure polyaspartic/polyurea concrete coatings are 4X stronger and 5X more flexible than epoxy. This means that they will not chip, crack or peel under extreme temperature change or heavy use. Our Polyurea/Polyaspartic Coatings are long lasting because they form a chemical bond with concrete. Because of the product’s strength and fast cure time, our installations require experienced professional installers.